Same symptoms I had, it looked like a fish tank air bubbler inside there. No bubbles since!Eastblock wrote:My Gaz has a K124 carb with a sight glass that lets you see the fuel level in the float chamber. After a tank stop it would not start and it was clear to see bubbles rising through the glass. As soon as it had cooled enough to stop bubling it started easily. I will definetely be making a spacer.

Carb spacer

Moderators: Charlesm, KarlJ, zoltan

Re: Carb spacer

Keeper of the local Soviet stuff.... What is that?.. It's a what?.... Where do you get parts for that?

Re: Carb spacer

As my vehicle is immobilised any way, I decided to have a play with the Tufnol spacer which my mechanic has now cut to shape. He had advised to insert thin paper gaskets on both sides of this, which I fabricated yesterday. This morning I removed the entire rig of air filter and carburettor, removed the old gasket and then tackled the studs. With a tiny bit of swearing...  they came off. The main nuisance was retrieving the nuts off them once they had come off. The thread of the studs is different on the two ends: it is M10 x 1.5 going into the manifold and that is easy to come by in any shape or form, but it is M10 x 1 on the carburettor end, and that's not a measure that is immediately available, so the two nuts were precious and had to retrieved, as I haven't got a stud extractor. In any case, I then proceeded to fabricated two longer studs from a threaded rod I had bought years ago when I had first thought of doing this job. As there isn't a lot of space between the top of the stud when mounted and the protruding volume control screw of the carburettor, the length of these studs has to be done conservatively: I knew that the spacer was 9.5 mm. thick, so aimed at cutting the studs 10 mm. longer than the old ones. Because sawing along the thread consumes a bit, I think I ended up with studs longer by 8.5 mm. I gingerly mounted everything and tried closing the bonnet: no problem. Having removed the side panel, I could check with my hands and there is still a gap between the very top of the air filter central stud and the bonnet above. One thing I should say here, which is likely to make a difference: in its original configuration, the air filter is kept together at the top by a wing nut. A long time ago I found out that this one has a tendency to wind itself out. It is tempting to screw it down, but the danger is to bend the mount on to which the air filter sits, reducing the air intake and strangling the engine... (guess how I found this out

they came off. The main nuisance was retrieving the nuts off them once they had come off. The thread of the studs is different on the two ends: it is M10 x 1.5 going into the manifold and that is easy to come by in any shape or form, but it is M10 x 1 on the carburettor end, and that's not a measure that is immediately available, so the two nuts were precious and had to retrieved, as I haven't got a stud extractor. In any case, I then proceeded to fabricated two longer studs from a threaded rod I had bought years ago when I had first thought of doing this job. As there isn't a lot of space between the top of the stud when mounted and the protruding volume control screw of the carburettor, the length of these studs has to be done conservatively: I knew that the spacer was 9.5 mm. thick, so aimed at cutting the studs 10 mm. longer than the old ones. Because sawing along the thread consumes a bit, I think I ended up with studs longer by 8.5 mm. I gingerly mounted everything and tried closing the bonnet: no problem. Having removed the side panel, I could check with my hands and there is still a gap between the very top of the air filter central stud and the bonnet above. One thing I should say here, which is likely to make a difference: in its original configuration, the air filter is kept together at the top by a wing nut. A long time ago I found out that this one has a tendency to wind itself out. It is tempting to screw it down, but the danger is to bend the mount on to which the air filter sits, reducing the air intake and strangling the engine... (guess how I found this out  ) So to solve the problem, I removed the wing nut and now have a Nyloc nut on top which does not move. I suspect that the wings of the wing nut might be more of an issue possibly touching the bonnet. With my Nyloc nut, nothing touches. I even fired the engine to check that everything was as intended, and could not hear any banging against the bonnet. So the message is that a spacer as thick as 9.5 mm. can be fitted without major surgery to the bodywork. Whether I shall get the Bhp improvements that Haymish was suggesting (sadly there is no taper) will have to wait until the clutch is sorted...

) So to solve the problem, I removed the wing nut and now have a Nyloc nut on top which does not move. I suspect that the wings of the wing nut might be more of an issue possibly touching the bonnet. With my Nyloc nut, nothing touches. I even fired the engine to check that everything was as intended, and could not hear any banging against the bonnet. So the message is that a spacer as thick as 9.5 mm. can be fitted without major surgery to the bodywork. Whether I shall get the Bhp improvements that Haymish was suggesting (sadly there is no taper) will have to wait until the clutch is sorted...

Re: Carb spacer

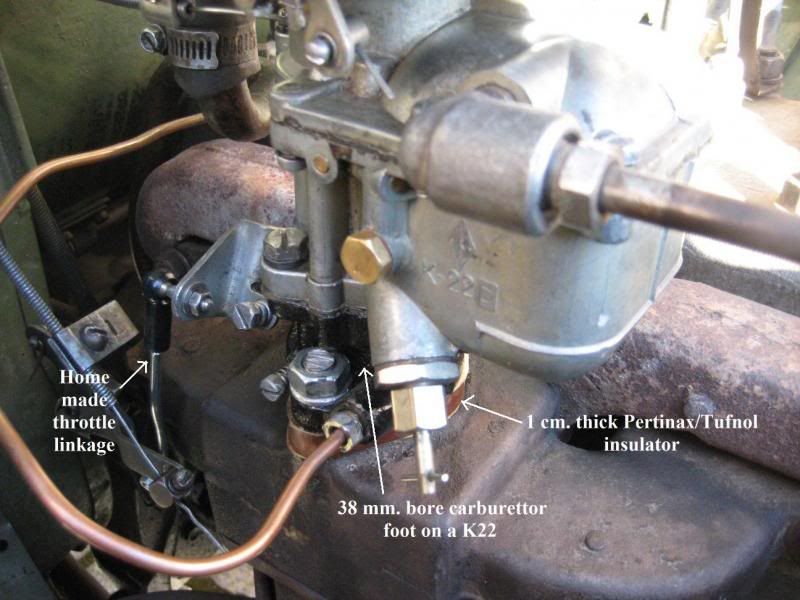

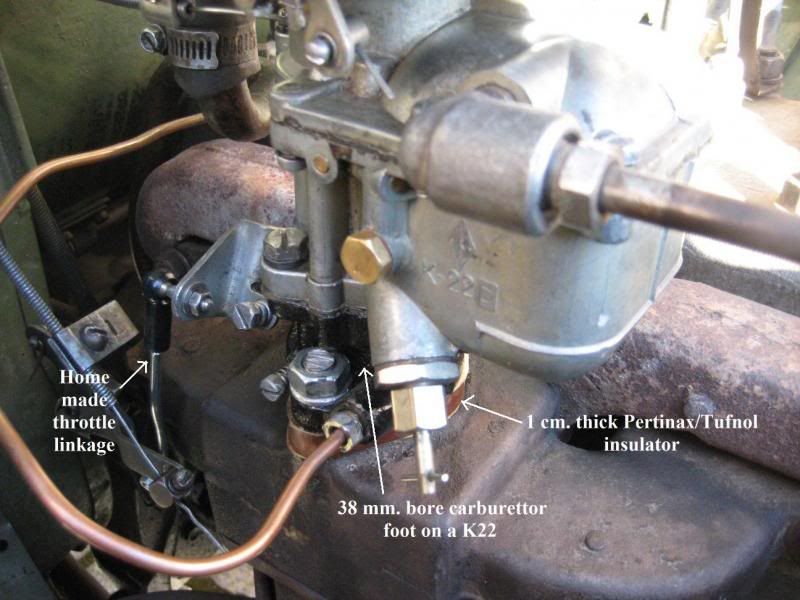

Here is a photograph of the carburettor in its new spaced-up version.

Given that Tony was helping me with the clutch, I took the opportunity to show the changes and he seems to think that they cannot do any harm ... The one worry I had was about the throttle linkages as the 1 cm. step might have limited the ability the open the full throttle with the pedal linkages as they stood, but Tony seems to think that they should be all right as they are, and in any case, there would be simple ways round it.

... The one worry I had was about the throttle linkages as the 1 cm. step might have limited the ability the open the full throttle with the pedal linkages as they stood, but Tony seems to think that they should be all right as they are, and in any case, there would be simple ways round it.

But I think I can confirm that the spacer I put in with 9.5 mm. thickness is really the maximum it can really take, without major changes to the bodywork, or re-positioning of the air filter. So assuming to want to remain substantially close to the original configuration, spacers of 9.5 mm and below should all be feasible.

Given that Tony was helping me with the clutch, I took the opportunity to show the changes and he seems to think that they cannot do any harm

But I think I can confirm that the spacer I put in with 9.5 mm. thickness is really the maximum it can really take, without major changes to the bodywork, or re-positioning of the air filter. So assuming to want to remain substantially close to the original configuration, spacers of 9.5 mm and below should all be feasible.

Re: Carb spacer

I shall have to confess that today I have reversed the operation and re-installed the old gasket  ...

...

I cannot quite say what was wrong... but something was not right. Let's say that the spirit of the vehicle visited my dreams and told me to do it... With the old set-up, I had last managed nearly to bridge the gap between second and third, and somehow the new arrangement had taken me back to square one. I also had doubts about the accelerator linkages and there is an obvious question mark on the air tightness of the paper gaskets I had fabricated. I am sure the theory is the right one and that it can all be sorted, but with Beltring round the corner, I am not in the mood for experimenting.

having re-installed the old gasket everything went back to where it was, which is good.

I cannot quite say what was wrong... but something was not right. Let's say that the spirit of the vehicle visited my dreams and told me to do it... With the old set-up, I had last managed nearly to bridge the gap between second and third, and somehow the new arrangement had taken me back to square one. I also had doubts about the accelerator linkages and there is an obvious question mark on the air tightness of the paper gaskets I had fabricated. I am sure the theory is the right one and that it can all be sorted, but with Beltring round the corner, I am not in the mood for experimenting.

having re-installed the old gasket everything went back to where it was, which is good.

Re: Carb spacer

When replacing any gasket, should one add some gasket sealer? Previous owners on mine seemed very handy with brown coloured silicone. Thx Billiannima wrote:Here is a photograph of the carburettor in its new spaced-up version.

Given that Tony was helping me with the clutch, I took the opportunity to show the changes and he seems to think that they cannot do any harm... The one worry I had was about the throttle linkages as the 1 cm. step might have limited the ability the open the full throttle with the pedal linkages as they stood, but Tony seems to think that they should be all right as they are, and in any case, there would be simple ways round it.

But I think I can confirm that the spacer I put in with 9.5 mm. thickness is really the maximum it can really take, without major changes to the bodywork, or re-positioning of the air filter. So assuming to want to remain substantially close to the original configuration, spacers of 9.5 mm and below should all be feasible.

Re: Carb spacer

You can do for most situations, it normally won't do any harm to use a bit, but remember if it's anything that comes into contact with fuel make sure the sealant is fuel resistant, Hylomar blue is and it's an easy one to get hold of i.e. Motor World/Halfords/Check Point etc.

“There is something fascinating about science. One gets such wholesale returns of conjecture out of such a trifling investment of fact.”

Mark Twain

Mark Twain

Re: Carb spacer

I resurrect this thread, which -to my mind- counts as one of the great classics that this forum has produced  . I like to think that members go over it again on wet afternoons...

. I like to think that members go over it again on wet afternoons...

Any way... the point is that I am currently playing with carbs, and I have managed to get the second one I own (purchased from Lahti) to work. This is a K22 which is marked with an R on the side and whose jets apparently match this suffix, but whose foot is with a 38 mm. bore instead of the 33 mm. one that is normally to be found on a K22R (including my own pictured above). Here is the new one fitted:

Mounting this one sort of prompted implementing a number of other modifications, many of which had been covered here. Because this 38 mm. foot is also not as deep as the 33 mm. one, inserting a slab of Pertinax/Tufnol of nearly 1 cm. helps, because a number of other things would otherwise be out of alignment (e.g. fuel pipe from the pump and air filter housing). It is true that these things could be modified but not too easily.

Any way... the point is that I am currently playing with carbs, and I have managed to get the second one I own (purchased from Lahti) to work. This is a K22 which is marked with an R on the side and whose jets apparently match this suffix, but whose foot is with a 38 mm. bore instead of the 33 mm. one that is normally to be found on a K22R (including my own pictured above). Here is the new one fitted:

Mounting this one sort of prompted implementing a number of other modifications, many of which had been covered here. Because this 38 mm. foot is also not as deep as the 33 mm. one, inserting a slab of Pertinax/Tufnol of nearly 1 cm. helps, because a number of other things would otherwise be out of alignment (e.g. fuel pipe from the pump and air filter housing). It is true that these things could be modified but not too easily.

Re: Carb spacer

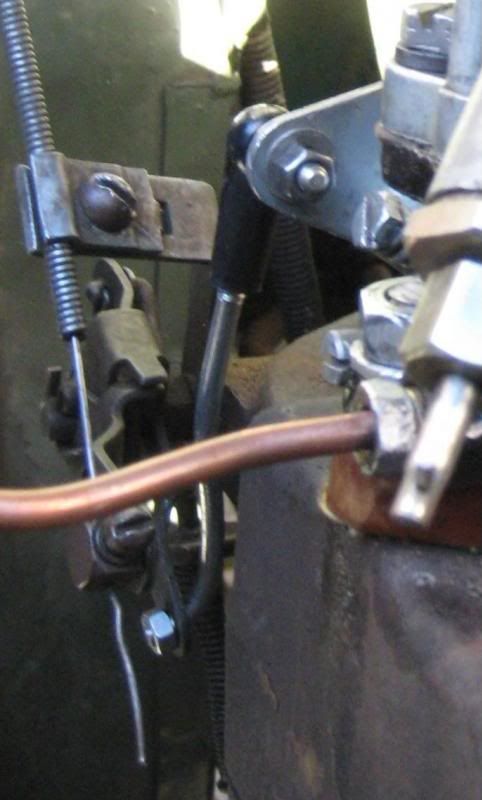

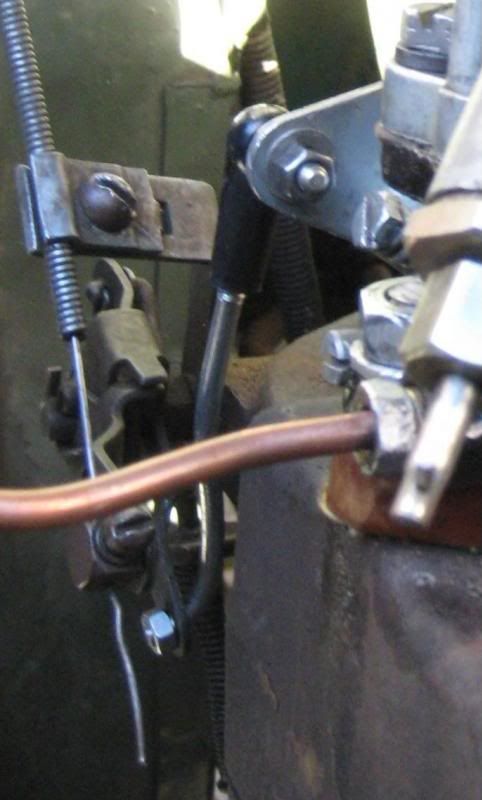

On the other hand, as mentioned elsewhere, one modification I had to undertake was fabricating a new throttle linkage roughly 1 cm. longer than the original. I first thought that I could get away with a universal one like this:

http://www.ebay.co.uk/itm/360641206390? ... 1439.l2649

but found out that the bottom end of this link needs to slide through various other levers and connections and the bulky ball connector would not clear these. I am glad that I opted for the cheaper version, because I would have had the same problem with more expensive (and elegant) versions. I tried to bend the threaded rod to do a 90 degrees angle, which is, after all, how the original linkage solves the problem, but it just snapped

I am rather ashamed about what I did then...

as I am certainly not going to win any prizes for elegance and philological purity...

as I am certainly not going to win any prizes for elegance and philological purity...  but I stumbled upon a long eye hook in an ironmonger's shop that looked like it was the right thickness... for the exorbitant price of 59p.

but I stumbled upon a long eye hook in an ironmonger's shop that looked like it was the right thickness... for the exorbitant price of 59p.

I heated it up and bent it in the vice so as to replicate the S shape of the original linkage... One ball joint was fitted to the threaded end of it. The hook was decapitated at the right level, once I had achieved the 90 degrees bend I wanted. I then force threaded onto it a nut of the right size. the original has a split pin, but I could not imagine my being able to drill that end so precisely. So here is this Frankenstein of a throttle linkage...

I might be deluding myself... but I don't think it looks that much worse than the original, whose ball joint looked VERY worn in any case...

http://www.ebay.co.uk/itm/360641206390? ... 1439.l2649

but found out that the bottom end of this link needs to slide through various other levers and connections and the bulky ball connector would not clear these. I am glad that I opted for the cheaper version, because I would have had the same problem with more expensive (and elegant) versions. I tried to bend the threaded rod to do a 90 degrees angle, which is, after all, how the original linkage solves the problem, but it just snapped

I am rather ashamed about what I did then...

I heated it up and bent it in the vice so as to replicate the S shape of the original linkage... One ball joint was fitted to the threaded end of it. The hook was decapitated at the right level, once I had achieved the 90 degrees bend I wanted. I then force threaded onto it a nut of the right size. the original has a split pin, but I could not imagine my being able to drill that end so precisely. So here is this Frankenstein of a throttle linkage...

I might be deluding myself... but I don't think it looks that much worse than the original, whose ball joint looked VERY worn in any case...

Re: Carb spacer

Now the BIG question that still awaits an answer is whether the insertion of this spacer will have the Bhp boosting effects that Haymish was telling us about. This, in any case, will not be a like for like comparison because the carburettor too is different, and I had a bit of a headache to try and smooth its running...  which might not be over yet... But all things considered, I have now solved a couple of the problems that had prevented me from further experimenting down this path in June last year...

which might not be over yet... But all things considered, I have now solved a couple of the problems that had prevented me from further experimenting down this path in June last year...

Re: Carb spacer

Oh, you were also having fun then!

The throttle linkage doesn't look that bad at all .

.

I still doubt the power increase due only to this spacer. Mind you, I do understand the theory behind it and the practical use in high output engines, and I will be the first to admit if proven wrong, but I think that a lot of other factors (like the low vacuum, the friction (drag), the turbulence, etc.) will have to be tackled first on our old, low output, engines before any measurable power increase could be noticed.

I also bought some popcorn and I'm eagerly awaiting the results of your further experimenting.

and I'm eagerly awaiting the results of your further experimenting.

The throttle linkage doesn't look that bad at all

I still doubt the power increase due only to this spacer. Mind you, I do understand the theory behind it and the practical use in high output engines, and I will be the first to admit if proven wrong, but I think that a lot of other factors (like the low vacuum, the friction (drag), the turbulence, etc.) will have to be tackled first on our old, low output, engines before any measurable power increase could be noticed.

I also bought some popcorn

Re: Carb spacer

I have guests arriving today and staying for a week, which will prevent my doing much testing...

If I am not completely mistaken, the following can be a very rough summary of Haymish's points in this thread:

in this thread:

1) That lengthening the channel between carb and manifold, can prevent bouncing back of gases slowing up the acceleration and the revving of the engine;

2) That a mismatch in the bore of the carb relative to that in the manifold can lead to undesirable effects in the flow of gases, with some potential loss of power;

3) That a taper in a spacer between carb and manifold as for point 1, can further speed up the gases, possibly with some increase in power.

The insertion of such a spacer is in any case motivated by what Lahti did originally, and what most of us have to do, in order to increase the level of insulation between carb and manifold, and prevent vapour locks. We can call it the Lahti point on to which all Haymish's ones constitute additional arguments for making the spacer thicker and possibly tapered. To give everybody their due, I will add that point 2 is also supported by Dirk Baumbach on the German forum.

on to which all Haymish's ones constitute additional arguments for making the spacer thicker and possibly tapered. To give everybody their due, I will add that point 2 is also supported by Dirk Baumbach on the German forum.

By my having installed this carb in this way, I am JOINTLY testing Haymish's point 1 and 2 (and obviously Lahti's original one) but not 3, because my mechanic could not cut the Tufnol with a taper. Haymish had suggested a spacer 1 inch thick = 2.54 cm. which cannot be done without more intrusive modifications, so the test of point 1 is limited to a spacer of 0.95 cm. The test of point 2 is however a full one, because I now have matching 38 mm. bore in carb and manifold.

My old engine remains the under-powered one that it is, relative to similar 2.12 side valve Gaz ones, and the transmission setup (not to mention common sense ) limit the "top" speed... However any better throttle response at low revving (and low speed) would still be desirable...

) limit the "top" speed... However any better throttle response at low revving (and low speed) would still be desirable...

If I get anywhere with this, I might refit the K22R carb at 33 mm. bore with the spacer still in place to test point 1 on its own...

So much testing so little time...

If I am not completely mistaken, the following can be a very rough summary of Haymish's points

1) That lengthening the channel between carb and manifold, can prevent bouncing back of gases slowing up the acceleration and the revving of the engine;

2) That a mismatch in the bore of the carb relative to that in the manifold can lead to undesirable effects in the flow of gases, with some potential loss of power;

3) That a taper in a spacer between carb and manifold as for point 1, can further speed up the gases, possibly with some increase in power.

The insertion of such a spacer is in any case motivated by what Lahti did originally, and what most of us have to do, in order to increase the level of insulation between carb and manifold, and prevent vapour locks. We can call it the Lahti point

By my having installed this carb in this way, I am JOINTLY testing Haymish's point 1 and 2 (and obviously Lahti's original one) but not 3, because my mechanic could not cut the Tufnol with a taper. Haymish had suggested a spacer 1 inch thick = 2.54 cm. which cannot be done without more intrusive modifications, so the test of point 1 is limited to a spacer of 0.95 cm. The test of point 2 is however a full one, because I now have matching 38 mm. bore in carb and manifold.

My old engine remains the under-powered one that it is, relative to similar 2.12 side valve Gaz ones, and the transmission setup (not to mention common sense

If I get anywhere with this, I might refit the K22R carb at 33 mm. bore with the spacer still in place to test point 1 on its own...

So much testing so little time...

Re: Carb spacer

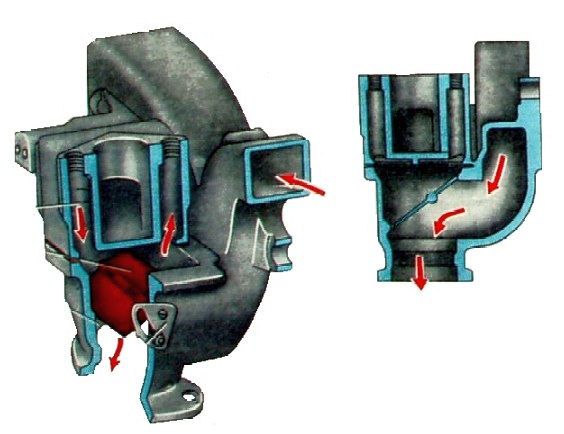

As to your point 1, I would like to remark that there are no gases bouncing back, it is a pressure wave traveling at the speed of sound back to the plenum which, due to it's large size (section) contains gases at low speed and (thus) high pressure and acts therefor as a spring sending the pressure wave back to the valve. In case the plenum is not able to send the wave back, it will hit the bottom of the carb and this pressure will obstruct the mixture coming from the carb to enter the plenum. This causes the "spitting back".

The carb spacers Haymish is referring to, increase the height of the total plenum, or, in other words, increase the spring function. This will return better the pressure wave before it reaches the bottom of the carb.

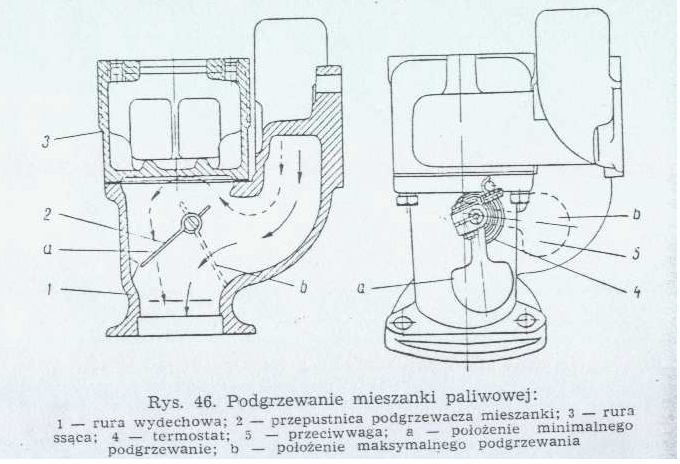

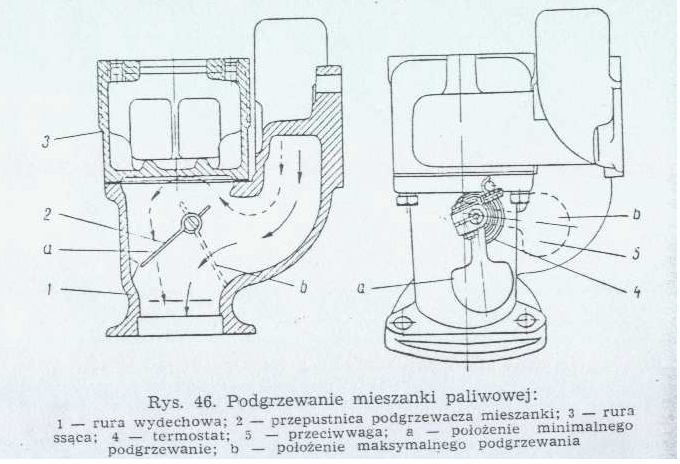

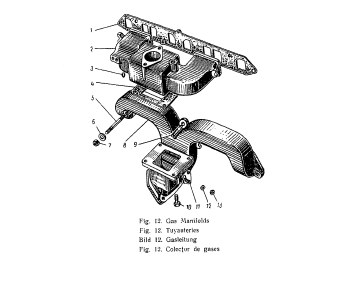

The manifold I was using has a cubic shaped plenum of the following dimensions l=90mm, w=70mm and h=65mm. In the roof of the plenum is then this hole of a diameter of 38mm for the carb. See cross section below:

Putting a spacer on top with the same opening would not really increase the plenum (at least not that part of the plenum that has a high pressure), it would only prolong the bottom section of the carb (which, due to its smaller section has gases travelling faster but at lower pressure. If this carb was spitting back, this spacer would not help much preventing it.

In my eternal quest for originality, I was able to obtain a manifold with the correct part numbers for an M20 (2,12l) engine. I was convinced that this manifold only differed in the size of the carb hole but no, the shape of the plenum is totally different. See cross section below:

The plenum here is actually only the extension of the hole in the roof which means it is first much smaller in size (smaller spring function, more prone to spitting back) but in this case the spacer would prolong the total height of the total plenum and thus would reduce the possibility of spitting back.

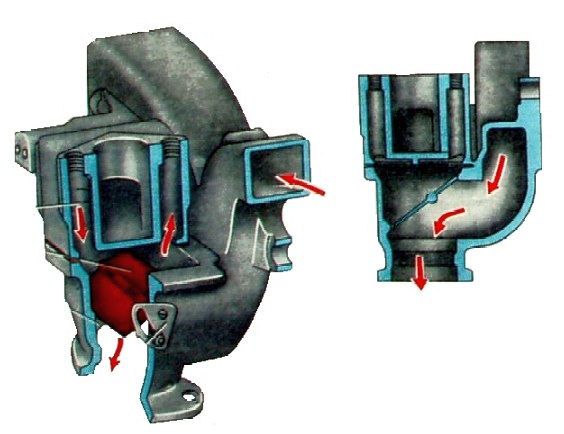

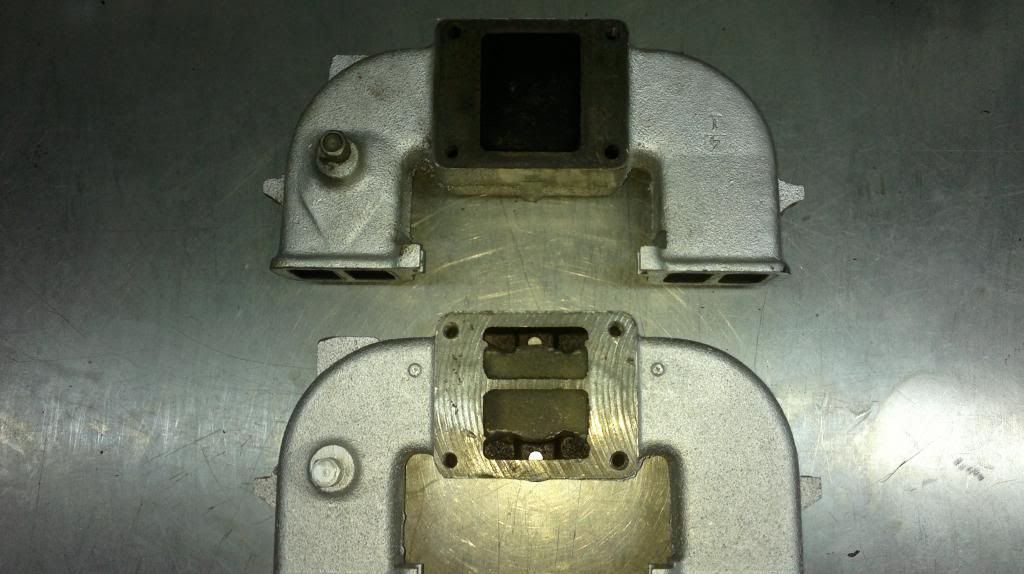

These are the two different manifolds;

Generally, I can say that the left one (for a 2,12l engine) is machined way better than the right one (for the 2,43l engine). All internal edges are better rounded and the intake runners are much smoother. In all fairness, I have to say that the right manifold bears no part numbers and misses the cast in fixation point of the heat shield, so maybe it isn't factory produced(?). But the right one has a carb opening of 38mm, where the opening of the left one, to my surprise, measures 36mm instead of the 33mm of the carb bottom hole (so much for your point 2). The section of the intake runners are identical as visible on the next picture;

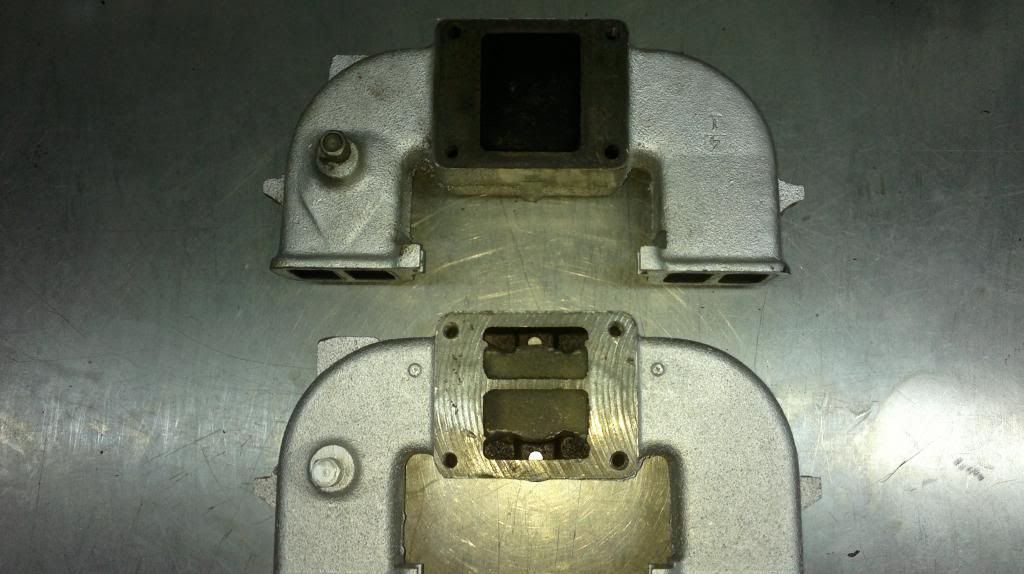

On the following picture of the bottom of the two inlet manifolds, the different plenum shape is clearly visible here;

And this picture shows the top of the 2,12l engine manifold.

As for the inertial supercharging, it is important to note that the intake runners on each side of the plenum have different lengths. IF inertial supercharging would take place in these engines, it would happen only in two cylinders at a given rpm, and in the other two cylinders at another rpm but it could be an explanation for our odd firing sequence. With 1-2-4-3, one would operate an alternating long-short-long-short intake runner and as such distribute better the difference in power (at certain rpm's in certain cylinders) to the crankshaft.

As for point 3, Haymish advised to taper the spacer 1-2mm inwards from carb to manifold, meaning the section at the manifold smaller as the section at the carb. For me this would mean from 33mm (carb) to 31mm, and then back to 36mm (manifold)? On all pictures of 4 port spacers, I saw them or straight or tapered outwards as on the picture below;

The carb spacers Haymish is referring to, increase the height of the total plenum, or, in other words, increase the spring function. This will return better the pressure wave before it reaches the bottom of the carb.

The manifold I was using has a cubic shaped plenum of the following dimensions l=90mm, w=70mm and h=65mm. In the roof of the plenum is then this hole of a diameter of 38mm for the carb. See cross section below:

Putting a spacer on top with the same opening would not really increase the plenum (at least not that part of the plenum that has a high pressure), it would only prolong the bottom section of the carb (which, due to its smaller section has gases travelling faster but at lower pressure. If this carb was spitting back, this spacer would not help much preventing it.

In my eternal quest for originality, I was able to obtain a manifold with the correct part numbers for an M20 (2,12l) engine. I was convinced that this manifold only differed in the size of the carb hole but no, the shape of the plenum is totally different. See cross section below:

The plenum here is actually only the extension of the hole in the roof which means it is first much smaller in size (smaller spring function, more prone to spitting back) but in this case the spacer would prolong the total height of the total plenum and thus would reduce the possibility of spitting back.

These are the two different manifolds;

Generally, I can say that the left one (for a 2,12l engine) is machined way better than the right one (for the 2,43l engine). All internal edges are better rounded and the intake runners are much smoother. In all fairness, I have to say that the right manifold bears no part numbers and misses the cast in fixation point of the heat shield, so maybe it isn't factory produced(?). But the right one has a carb opening of 38mm, where the opening of the left one, to my surprise, measures 36mm instead of the 33mm of the carb bottom hole (so much for your point 2). The section of the intake runners are identical as visible on the next picture;

On the following picture of the bottom of the two inlet manifolds, the different plenum shape is clearly visible here;

And this picture shows the top of the 2,12l engine manifold.

As for the inertial supercharging, it is important to note that the intake runners on each side of the plenum have different lengths. IF inertial supercharging would take place in these engines, it would happen only in two cylinders at a given rpm, and in the other two cylinders at another rpm but it could be an explanation for our odd firing sequence. With 1-2-4-3, one would operate an alternating long-short-long-short intake runner and as such distribute better the difference in power (at certain rpm's in certain cylinders) to the crankshaft.

As for point 3, Haymish advised to taper the spacer 1-2mm inwards from carb to manifold, meaning the section at the manifold smaller as the section at the carb. For me this would mean from 33mm (carb) to 31mm, and then back to 36mm (manifold)? On all pictures of 4 port spacers, I saw them or straight or tapered outwards as on the picture below;

Re: Carb spacer

Right...  I report that I have now RE-installed the K22P (R) with 33 mm. bore onto the same 38 mm bored, 9.5 mm thick spacer.

I report that I have now RE-installed the K22P (R) with 33 mm. bore onto the same 38 mm bored, 9.5 mm thick spacer.

I cannot quite say why , but there simply was a hiccup at idle that I could not get rid of in any way with the hybrid K22 with 38 mm. bore. It seemed to work fine at any other regime but at idle, when there was a discontinuity that could not be classed as a misfire, but equally prevented smooth running. So having tried everything I could (cleaned jets, adjusted timing) I gave up and took it off. Funnily enough Lahti too said that there was something he could not smooth with this carb, and I got it from him. Possibly the gasket between float chamber and the foot would have to be checked for air leaks and flatness of the surfaces...

In any case, now I am back with the K22P (R). The running is now VERY smooth at all regimes. It will have to be said that once I got it off the vehicle, I have reconditioned this carb as far as I could go, on my own, with all jets having been replaced with brand new clean ones and having also fitted a brand new gasket between float chamber and top. So again this is not a clear cut test of Haymish point 1 (as further elaborated by Geronimo)

For what it is worth, I report that, with the top speed remaining the same as before for obvious reasons, I think I can now feel greater ease and flexibility in getting there...

I tackled today a road I know very well, where I can compare performance (such as it is ) rather accurately. There is one hill where I can feel the engine slowing down...

) rather accurately. There is one hill where I can feel the engine slowing down...  regardless of what advance momentum I can give it. Before changing the distributor to the Russian one, and therefore still with the DDR one, the best I could hope for was to reach the top in third gear at 50 Kmh. A very strangled third but still third (top gear

regardless of what advance momentum I can give it. Before changing the distributor to the Russian one, and therefore still with the DDR one, the best I could hope for was to reach the top in third gear at 50 Kmh. A very strangled third but still third (top gear  ). With the Russian distributor I have been able to do it at 55 Kmh nearly 60. Today I must have been above 65 Kmh and I even managed to overtake a bus (admittedly a VERY slow one)... in a rather comfortable third gear.

). With the Russian distributor I have been able to do it at 55 Kmh nearly 60. Today I must have been above 65 Kmh and I even managed to overtake a bus (admittedly a VERY slow one)... in a rather comfortable third gear.

Third gear is now able to range from just 40 Kmh (not comfortable) and will pick up revs to its comfortable range of 60 Kmh, all the way to the maximum (sensible) speed of 70-75 Kmh. I have had moments when the needle seemed to want to go to 80 Kmh, but I have no wish to push it that way...

As I said it might just be the cleaned carb, but there might be something here...

I cannot quite say why , but there simply was a hiccup at idle that I could not get rid of in any way with the hybrid K22 with 38 mm. bore. It seemed to work fine at any other regime but at idle, when there was a discontinuity that could not be classed as a misfire, but equally prevented smooth running. So having tried everything I could (cleaned jets, adjusted timing) I gave up and took it off. Funnily enough Lahti too said that there was something he could not smooth with this carb, and I got it from him. Possibly the gasket between float chamber and the foot would have to be checked for air leaks and flatness of the surfaces...

In any case, now I am back with the K22P (R). The running is now VERY smooth at all regimes. It will have to be said that once I got it off the vehicle, I have reconditioned this carb as far as I could go, on my own, with all jets having been replaced with brand new clean ones and having also fitted a brand new gasket between float chamber and top. So again this is not a clear cut test of Haymish point 1 (as further elaborated by Geronimo)

For what it is worth, I report that, with the top speed remaining the same as before for obvious reasons, I think I can now feel greater ease and flexibility in getting there...

I tackled today a road I know very well, where I can compare performance (such as it is

Third gear is now able to range from just 40 Kmh (not comfortable) and will pick up revs to its comfortable range of 60 Kmh, all the way to the maximum (sensible) speed of 70-75 Kmh. I have had moments when the needle seemed to want to go to 80 Kmh, but I have no wish to push it that way...

As I said it might just be the cleaned carb, but there might be something here...

Last edited by iannima on Thu Nov 07, 2013 12:28 pm, edited 3 times in total.

Re: Carb spacer

Slightly off topic but it might help with some of the issues mentioned.

It looks in the pictures that your fuel supply line is running quite close to the exhaust manifold, near the bulkhead, a classic cause of vapour lock, also your carb being directly above the exhaust manifold might benefit from some sort of heat shield, especially the float bowl.

cheers

It looks in the pictures that your fuel supply line is running quite close to the exhaust manifold, near the bulkhead, a classic cause of vapour lock, also your carb being directly above the exhaust manifold might benefit from some sort of heat shield, especially the float bowl.

cheers

Re: Carb spacer

This is not off topic, because the very first reason to want a carb spacer in Tufnol/Pertinax is precisely to provide better insulation to the carb from the heat of the manifold (Lahti's original point). The subsequent arguments (Haymish's points) were on why to make it thicker for other reasons.redneck wrote:Slightly off topic but it might help with some of the issues mentioned.

It looks in the pictures that your fuel supply line is running quite close to the exhaust manifold, near the bulkhead, a classic cause of vapour lock, also your carb being directly above the exhaust manifold might benefit from some sort of heat shield, especially the float bowl.

cheers

Heat shields are sometimes mounted on the front part of the manifold (Geronimo is looking for one) to obviate to this problem, but I am not clear that they were an original fitting. In fact I am pretty certain they weren't. My fuel line bends as far away from the engine as it can precisely for that reason. and it cannot go any further (without cutting the body...

Like many, I too have had problems of vapour lock, but these were exclusively cases of trouble in re-starting the engine when hot. All of these disappeared when I fitted a thicker gasket intended for a Weber carb. Once running, I have never had an issue of such locks in the fuel lines and I would have noticed them pretty quickly.

Re: Carb spacer

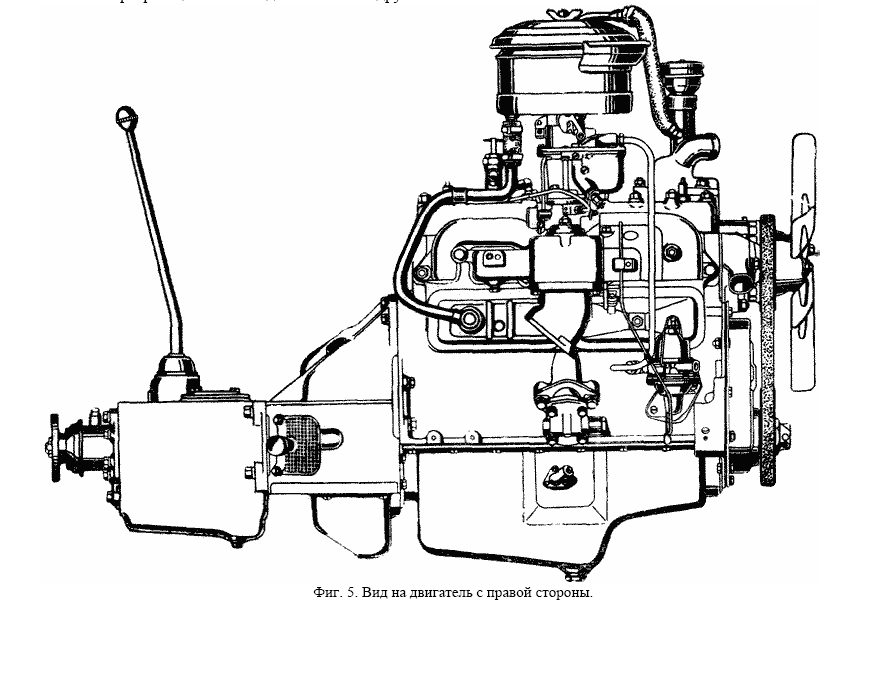

I am pretty sure they were an original fitting because they are pictured in the 1956 manual.iannima wrote: Heat shields are sometimes mounted on the front part of the manifold (Geronimo is looking for one) to obviate to this problem, but I am not clear that they were an original fitting. In fact I am pretty certain they weren't.

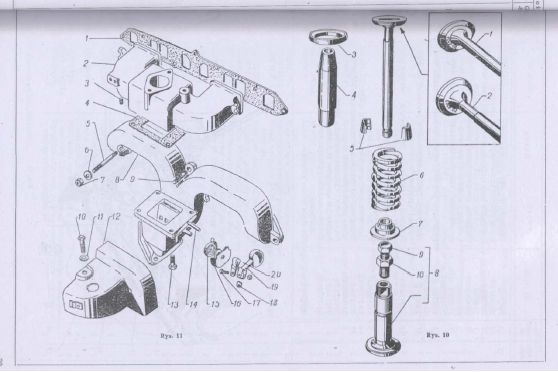

They are also mentioned in the 1959 spare part catalog for the Gaz 69 (A) where they even have their own part number 69-1008098. On the drawing number 11 here below, the shield is number 12, the part number is in the list.

They were deleted in the multi-language spare part catalog for the export version Gaz 69M (AM) (I have no idea why), but the stud on the manifold to fix them is still there. There are manifolds without these studs, most probably for other cars, because the part number of the heat shield starts with "69", meaning it was related to the Gaz 69 only.

The line running near the bulkhead is the vacuum line to the distributor. The fuel line is the thicker one going down to the fuel pump. This line would be also "protected" by the heat shield, on condition, of-course, that this shield is effective. But to check this efficiency one has to have oneredneck wrote: It looks in the pictures that your fuel supply line is running quite close to the exhaust manifold, near the bulkhead

Re: Carb spacer

You know I had never noticed? But I can confirm that the fitting for the retaining stud is absent on both my currently fitted manifold and on my new one:

...and it is absent on your 21 manifold too...

In any case, I continue to hold that any problem of vapour lock I might have had were satisfactorily dealt with a better gasket between carb and manifold. The original is a joke... and I have my doubts that the heat shields would have much of an effect. The problem of hot starting develops if one leaves the engine stopped for several minutes, like at re-fuelling at a petrol station. If one tries to restart STRAIGHT after stopping it, there is no such problem. To my mind, the issue is that once the engine is stopped, the heat starts expanding from the engine core to the periphery. Given enough time and no effective insulation between carb and manifold, it will heat up the float chamber of the carb, resulting in vapourisation of the petrol inside, and this will primarily happen through the foot of the carb which is in direct contact with the hot manifold.

The Germans have sometimes solved the problem with an electric fuel pump. In my experience, the original mechanical pump, with a good battery and starter motor will also work, and any hesitation was quickly solved with a 5 mm. gasket such as this one:

http://www.ebay.co.uk/itm/WEBER-34-ICH- ... 53f9fee67e

which I have used for years. So I suspect that they too had realised that the heat shield was not doing much and deleted it.

...and it is absent on your 21 manifold too...

In any case, I continue to hold that any problem of vapour lock I might have had were satisfactorily dealt with a better gasket between carb and manifold. The original is a joke... and I have my doubts that the heat shields would have much of an effect. The problem of hot starting develops if one leaves the engine stopped for several minutes, like at re-fuelling at a petrol station. If one tries to restart STRAIGHT after stopping it, there is no such problem. To my mind, the issue is that once the engine is stopped, the heat starts expanding from the engine core to the periphery. Given enough time and no effective insulation between carb and manifold, it will heat up the float chamber of the carb, resulting in vapourisation of the petrol inside, and this will primarily happen through the foot of the carb which is in direct contact with the hot manifold.

The Germans have sometimes solved the problem with an electric fuel pump. In my experience, the original mechanical pump, with a good battery and starter motor will also work, and any hesitation was quickly solved with a 5 mm. gasket such as this one:

http://www.ebay.co.uk/itm/WEBER-34-ICH- ... 53f9fee67e

which I have used for years. So I suspect that they too had realised that the heat shield was not doing much and deleted it.

Re: Carb spacer

I agree on all accounts and I also have doubts about the effect of the heat shield when the car is stationary but it was there originally and I would like to test the behavior of my engine without any precautions, with the spacer only, with the heat shield only and with both of them installed.iannima wrote:In any case, I continue to hold that any problem of vapour lock I might have had were satisfactorily dealt with a better gasket between carb and manifold. The original is a joke... and I have my doubts that the heat shields would have much of an effect.

Anyhow, if it doesn't help, it will not harm.

Re: Carb spacer

For some time, I have been meaning to write a Post Scriptum to this now classic thread

It will be recalled that the original point for wanting to install some better insulation between carburettor and manifold is to avoid the well known problems of hot starting, and that remains the main reason for experimenting with Tufnol (or Pertinax) spacers. I have referred to this above as the Lahti (I miss him

(I miss him  ) point.

) point.

I now have a refurbished 2.43 engine instead of the very under-powered 2.12. From January all through the Spring I have swapped K124 and K22R carbs many times over and still getting hiccups on acceleration . I eventually traced the problem to a tiny air leak between the Tufnol spacer and one of the paper gaskets that sandwich it. I therefore went back to the thicker gasket that is used for Weber carbs, which I had used for some time with excellent results:

. I eventually traced the problem to a tiny air leak between the Tufnol spacer and one of the paper gaskets that sandwich it. I therefore went back to the thicker gasket that is used for Weber carbs, which I had used for some time with excellent results:

But I still felt that something was not 100% right. In the first place I noticed tiny bubbles in the float chamber when idling after a longish ride. Secondly I had noticed that the response at low revs was not what it used to be .

.

Things came to a head in August when I had serious trouble restarting the engine after a trip to Sainsbury's. The bubbles to be seen, thanks to the window in the K124, were truly unbelievable . At that stage I decided that I needed to go back to the Tufnol spacer.

. At that stage I decided that I needed to go back to the Tufnol spacer.

I therefore removed the Weber gasket and found, to my surprise, that it had deformed rather badly. One of its various layers was protruding a bit (in a frayed state) over the centre bore Now that cannot have helped at all

Now that cannot have helped at all

I had made some more paper gaskets; smeared them with grease and reinstalled the Tufnol spacer which I had lightly rubbed, on both faces, with some emery paper. The swap demands longer studs to be fitted which I had kept.

First trials, already In August, have shown no air leaks which is all to the good.

which is all to the good.

Now after many more Km. I report that after a longish ride, I cannot see ANY bubble in the carb... not even tiny ones. So the Lahti point is addressed once again.

point is addressed once again.

But what it is also noticeable to me -and I had a further proof of it today- is that the low down (low revs) torque is substantially better. I can effectively back off the throttle in third gear and let the speed sink down to 30-35 Kmh (difficult to be precise ) and then accelerate again STILL in third and get back to the appropriate cruising speed. I certainly could not do that with the Weber gasket.

) and then accelerate again STILL in third and get back to the appropriate cruising speed. I certainly could not do that with the Weber gasket.

Whether this is due to the Weber gasket having gone bad (it certainly had) is difficult to say, but my gut feeling is that there actually IS evidence in favour of at least some of the points made by Haymish He had indeed said that lengthening the channel the gases had to negotiate was going to improve low down throttle response. I now feel that he is dead right

He had indeed said that lengthening the channel the gases had to negotiate was going to improve low down throttle response. I now feel that he is dead right  and that there is a perceptible difference even with a spacer of only 95 mm ( he had suggested one of 250 and tapered).

and that there is a perceptible difference even with a spacer of only 95 mm ( he had suggested one of 250 and tapered).

So the bottom line is that I would advise anybody to have one made

It will be recalled that the original point for wanting to install some better insulation between carburettor and manifold is to avoid the well known problems of hot starting, and that remains the main reason for experimenting with Tufnol (or Pertinax) spacers. I have referred to this above as the Lahti

I now have a refurbished 2.43 engine instead of the very under-powered 2.12. From January all through the Spring I have swapped K124 and K22R carbs many times over and still getting hiccups on acceleration

But I still felt that something was not 100% right. In the first place I noticed tiny bubbles in the float chamber when idling after a longish ride. Secondly I had noticed that the response at low revs was not what it used to be

Things came to a head in August when I had serious trouble restarting the engine after a trip to Sainsbury's. The bubbles to be seen, thanks to the window in the K124, were truly unbelievable

I therefore removed the Weber gasket and found, to my surprise, that it had deformed rather badly. One of its various layers was protruding a bit (in a frayed state) over the centre bore

I had made some more paper gaskets; smeared them with grease and reinstalled the Tufnol spacer which I had lightly rubbed, on both faces, with some emery paper. The swap demands longer studs to be fitted which I had kept.

First trials, already In August, have shown no air leaks

Now after many more Km. I report that after a longish ride, I cannot see ANY bubble in the carb... not even tiny ones. So the Lahti

But what it is also noticeable to me -and I had a further proof of it today- is that the low down (low revs) torque is substantially better. I can effectively back off the throttle in third gear and let the speed sink down to 30-35 Kmh (difficult to be precise

Whether this is due to the Weber gasket having gone bad (it certainly had) is difficult to say, but my gut feeling is that there actually IS evidence in favour of at least some of the points made by Haymish

So the bottom line is that I would advise anybody to have one made

Re: Carb spacer

I was wondering if Thermal paste from a computer CPU could have some effect or even sticking heatsinks on the manifold from an old PC with high thermal resistant glue ...i know i know it will not look pretty